민수사업 탭메뉴

- 반도체장비

- 자동화 장비

캐비닛

반도체 Package 또는 Chip을 Pick & Place 하는 모듈

칩마운터 상품 안내

제품개요

- 반도체 Package 또는 Chip을 Pick & Place 하는 모듈

제품 사양

| Stroke | Z-axis | 15 mm | |

|---|---|---|---|

| R-axis | Unlimited | ||

| Spindle | Pitch | 20 mm | |

| Number | 8-axis | ||

| 10-axis | |||

| Repeatibility | Z-axis | ±0.01 mm | |

| R-axis | ±0.05 deg | ||

| Speed | Z-axis | 500 mm/sec | |

| 8G | |||

| R-axis | 2,500 deg/sec | ||

| 110,000 deg/sec2 | |||

| Resolution | 0.005 mm | 27bit Encoder | |

| Servo Control | Pulse Input | ||

| EtherCat | Network Driver | ||

| Weight | 7.35 kg | ||

| Size(WxHxD) | 186 x 279 x 316 mm | ||

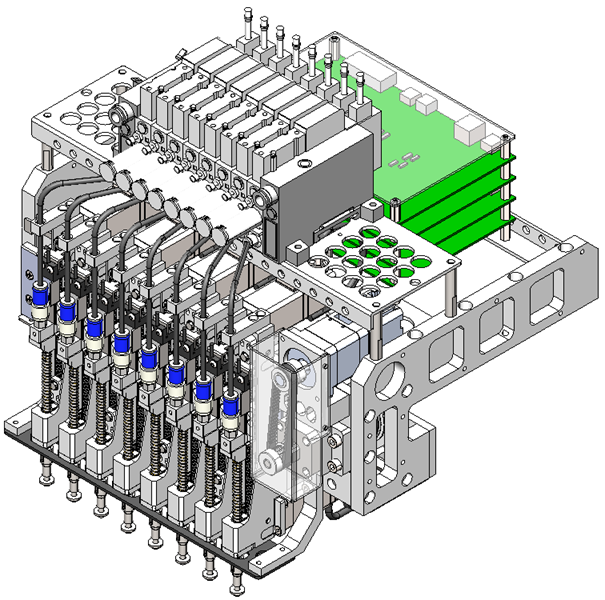

제품개요

- 반도체 Package 또는 Chip을 Pick & Place 하는 모듈

- Spindle 간의 Pitch를 가변하여 웨이퍼에서 절단된 부품을 동시에 Pick-up 하여 Tray에 동시에 Place 할 수 있는 Picker Module

제품 사양

| Spindle No. | 8 | ||

|---|---|---|---|

| Stroke | Z-axis | 25 mm | |

| P-axis | 14 ~ 28 mm | Pitch 가변 범위 | |

| Repeatibility | Z-axis | ±0.01 mm | |

| P-axis | ±0.03 mm | ||

| Spindle No. | 8 | ||

| Speed | Z-axis | 500 mm/sec | |

| 8G | |||

| P-axis | 500 mm/sec | ||

| 1G | |||

| Resolution | 0.005 mm | 27bit Encoder | |

| Servo Control | Pulse Input | ||

| EtherCat | Network Driver | ||

| Weight | 13.4 kg | ||

| Size(WxHxD) | 362 x 391 x 278 mm | ||

고객사의 니즈 충족 및 안정적인 OEM 방식

용도

- 솔라셀 표면 인쇄 장치

제품 사양

| 인쇄속도 | Cycle Time 5.0 sec |

|---|---|

| PCB Size | L350mm x W250mm |

| 인쇄 정도 | ±12.5㎛@6σ |

| 스텐실 | 650mm x 550mm |

| 550mm x 650mm (Option) |

용도

- Can connector 부품, LED, 렌즈 실장

구성

- HEAD

| 속도 | 82,000 CPH (Optimum) |

|---|---|

| 구조 | 10 Spindles X 2Gantry |

| 대응부품 | 0402 ~ 55mm(H15mm) |

- CONVEYOR Ass’y

| 조립공차 | 평면도 |

|---|---|

| 진직도 30μm이내 | |

| 정밀도 | ±40μm @ Cpk≥ 1.0/Chip |

| ±30μm @ Cpk≥ 1.0/IC |

적용 가능 칩마운터

- 엑센프로M, 엑센프로D 등

용도

- 대형 전장부품 및 삽입부품 실장

구성

- HEAD

| 속도 | 2,400CPH (1Spindle)/3,000CPH (2Spindle)) |

|---|---|

| 구조 | 1 Gantry x 25 Spindles |

| 대응부품 | 0201 ~ 6mm / ~ 55mm(H15mm) |

- CONVEYOR Ass’y

| 조립공차 | 평면도 |

|---|---|

| 진직도 30μm이내 | |

| 정밀도 | ±50μm @ Cpk≥ 1.0/Chip |

적용 가능 칩마운터

- Decan S2, L2, F2 등

칩마운터 홍보영상

4 Gantry 형 고속 모듈러 마운터 EXCEN PRO M

| 아이콘 | 설명 |

|---|---|

| 스펙 아이콘 |

속도

120,000 CPH (최적) |

| 스펙 아이콘 |

구조

4 Gantry x 2/8/16 Spindles/Head |

| 스펙 아이콘 |

장착정도

±35μm Cpk≥1.0 (Chip) |

| 스펙 아이콘 |

PCB Size

(Min) L50xW50mm |

| 스펙 아이콘 |

특징

초경량 고속∙고정도 전동피더 |

협동로봇

협동로봇 머리글

협동로봇VOLK의 뛰어난 기술로 구조해석을 통한 경량화, 내구성을 갖춘 협동로봇

협동로봇 상품 안내

Automated Assembly

제품설명- - 국내 최초 협동로봇

- - 가반중량 : 3 ~ 12kg(3kg, 5kg, 12kg)

- - 구성 축 : 6축

- - 작업반경 : 600~1300mm

- - 관절범위 : ±360°

Logistics Transfer

제품설명- - 가벼운 소형 로봇에 센서와 제어 장치 내장

- - 기존 로봇대비 적은 초기 투자비

- - 정밀한 반복작업 가능

- - 인건비 대폭 절감

Welding

제품설명- - 작업자와 동일 공간에서 작업 가능(안전성)

- - 세밀한 초정밀 작업 가능

- - 외부 충격 예측 / 감지시 자동으로 정지

- - 다이렉트 티칭 가능

Manufacturing

제품설명- - 다품종 소량생산체제 및 중소/중견기업에 적합

- - 비전문가 조작 가능

- - 유연한 작업 배치로 다양한 공정에 쉽고 빠르게 적용

협동로봇 홍보영상

Hanwha Collaborative Robotics (HCR-5)

| 아이콘 | 설명 |

|---|---|

| 스펙 아이콘 |

자유도

6축 관절 |

| 스펙 아이콘 |

가반중량

5 Kg |

| 스펙 아이콘 |

작업반경

915 mm |

| 스펙 아이콘 |

관절범위

±360° |

| 스펙 아이콘 |

무게

20 Kg |

| 스펙 아이콘 |

속도

각축: 180°/sec, 툴: 1m/sec |

자동화 장비 머리글

자동화 장비자동화 장비의 S/W 및 H/W 설계부터 장비의 운영까지, 전 공정에 대한 턴키 서비스 제공

자동화 장비 설명 슬라이드

커버 글라스 검사장비 / PITCH 가변 PICKER HEAD / LINE 자동화 장비

기구설계, 전장/제어 설계, S/W, H/W 설계 및 조립/가공, 스마트 팩토리 실현

콘솔 개발 역량 탭(목록)

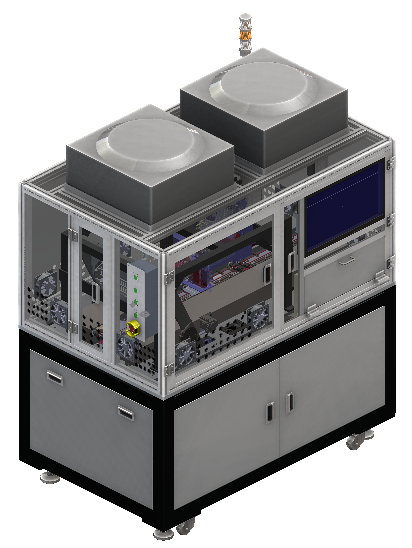

커버 글라스 검사장비 설명

MIL-STD Qualified

| 아이콘 | Index | Specifications |

|---|---|---|

| 자동화 장비 스펙 아이콘 | Dimension | (L)1600 x (W)1000 x (H)1945 |

| 자동화 장비 스펙 아이콘 | Glass Size | 3.5” ~ 6.5” |

| 자동화 장비 스펙 아이콘 | Detect Size | 10 um |

| 자동화 장비 스펙 아이콘 | Tact Time | Max. 5 sec |

| 자동화 장비 스펙 아이콘 | Detect | Scratch, Chipping, Stain, Dent, etc |

| 자동화 장비 스펙 아이콘 | Camera | Line Camera |

| 자동화 장비 스펙 아이콘 | Illumination | Reflection/Transmitance/Scattering |

Pitch 가변 Picker Head 설명

MIL-STD Qualified

| 아이콘 | 구분 | 항목 | 부호 | Spec | 단위 |

|---|---|---|---|---|---|

| 자동화 장비 스펙 아이콘 | Z축 | Pitch 가변 | 800 | mm/s | |

| Rated Speed | ± | 0.01 | mm | ||

| 반복정밀도 | ± | 0.01 | mm | ||

| 자동화 장비 스펙 아이콘 | 흔들림(Straightness) | Stroke | 16~25.5 | mm | |

| Rated Speed | 500 | mm/s | |||

| 반복정밀도 | ± | 0.05 | mm | ||

| 위치정밀도 | ± | 0.05 | mm |

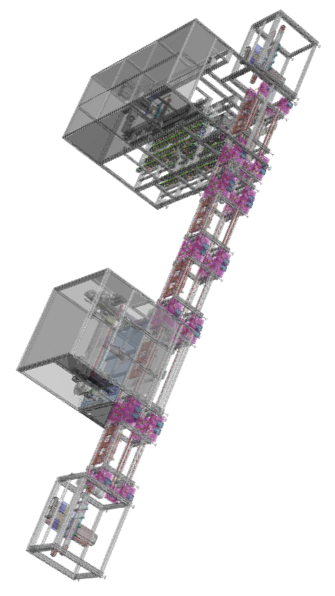

LINE 자동화 장비 설명

MIL-STD Qualified

| 아이콘 | 항목 | 성능 |

|---|---|---|

| 자동화 장비 스펙 아이콘 | Utility | 사용전원 (단상 220V, 60㎐) Air설정치 0.45 ±0.05㎫ |

| 자동화 장비 스펙 아이콘 | 구동부 | XYZ 직교 Robot(위치결정 정도: ±0.02㎜), 컨베어, LIFT, 롤러 |

| 자동화 장비 스펙 아이콘 | 설비제어방식 | PLC 또는 PC제어 |

| 자동화 장비 스펙 아이콘 | 소음 | 65 Db이하 |

| 자동화 장비 스펙 아이콘 | Cycle Time | 제품의 기본 LINE C/T을 고려(40초 이내) |

| 자동화 장비 스펙 아이콘 | 가동률 | 99.0%이상 |

| 자동화 장비 스펙 아이콘 | 불량발생률 | 0.01%이하 (10PPM 이하) |